Tesla Giga Factory, Among Others, May Cause Lithium Or Graphite Shortages

Oct. 6.16 |

Ron Struthers

Long/short equity, special situations, contrarian, Growth

Struthers Resource Stock Report

(679 followers)

Summary

12 Giga factories on the horizon.

Tesla's Elon Musk "should be called Nickle Graphite Batteries".

Four to Six times more Graphite required than Lithium.

Batteries - Lithium or Graphite - which is it?

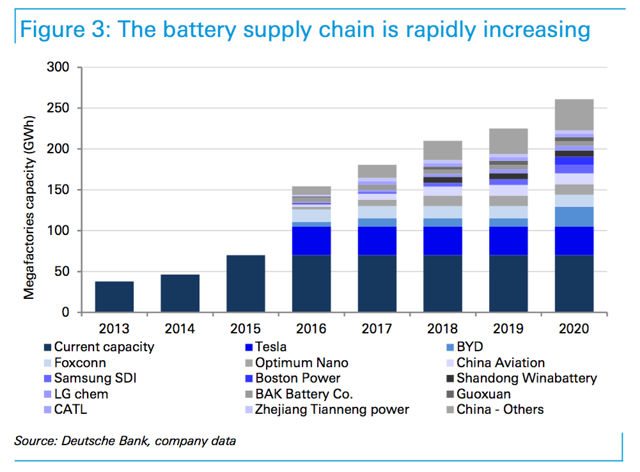

As investors, we have heard explosive growth stories for Lithium and Graphite from the rising demand for batteries, especially the numerous giga factories planned around the world. There are 12 planned between now and 2020, but most are in Europe and Asia, just two are in the U.S., in Nevada and Michigan.

Currently, over 60% of the demand for lithium and graphite is industrial use, but it is this anticipation of battery demand that gets all the optimistic forecasts

and it is deserving.

Currently, lithium is getting all the attention, but when I crunched all the facts and numbers, it is clear the graphite investor should reap higher rewards.

First, some important battery basics

They are called lithium ion batteries not because they are filled with lithium, but it is the powerful reaction of lithium and the movement of the lithium ion that provides the power or electricity.

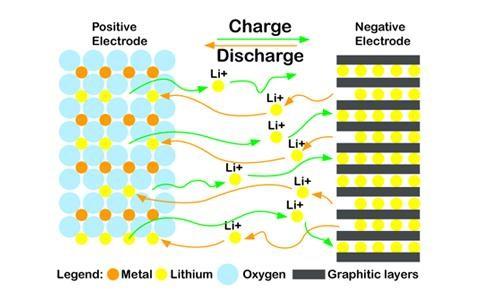

Inside the battery casing there is 3 basic components.

The Cathode that is typically a Lithium Nickel Cobalt Manganese Oxide. NCM for short and a successful combination is 5 parts nickel, 3 parts cobalt and 2 parts manganese.

The anode that is a graphite carbon that facilitates the absorption of lithium ions. Six Graphite atoms can hold 1 lithium atom, think of this as holding a charge.

And 3rd, the electrolyte that facilitates the movement of the lithium ion between the cathode and anode.

When a battery is used or discharges - the lithium ions move from the anode (graphite) to the cathode (nickel). When you recharge it, basically, you are moving the lithium ions back to the anode.

CEO, Elon Musk of

TESLA MOTORS (NASDAQ:

TSLA) recently commented,

"

Our cells should be called Nickel-Graphite, because primarily the cathode is nickel and the anode side is graphite with silicon oxide… [there's] a little bit of lithium in there, but it's like the salt on the salad,"

I believe he was down playing the lithium more than warranted.

Musk said that the amount of lithium in a lithium ion battery is about 2% of its total volume

Volume is probably not a good metric because lithium, graphite and nickel are all sold by weight, tons or pounds.

There is actually more nickel and cobalt in these batteries than lithium. Nickel is priced higher than graphite about $10,000 per ton and half the cobalt reserves are in a precarious place, The Congo. For this report, I am going to focus on the lithium and graphite.

Lithium

Lithium is highly reactive and its ions are bursting to get on the move. I can remember back in Chemistry class, that lithium only had to be exposed to water and would start an explosive reaction immediately.

This is why you have heard of battery fires and there are strict guidelines or restrictions on lithium ion battery shipping. The amount of lithium in a battery is quite common knowledge because of this. You can refer to some

regulations from UPS and their calculation on lithium content.

Just a couple weeks ago, Amazon (NASDAQ:

AMZN) was fined

$84,000 for shipping lithium ion batteries by air.

In the U.S. - Cells must not exceed 1.5 g of "equivalent lithium content"; - Batteries must not exceed 8 g of "equivalent lithium content." You may calculate "equivalent lithium content" by multiplying the cell's ampere-hours by 0.3. Since most small batteries are marked with milliampere-hours, you must first divide milliampere-hours by 1,000 before multiplying the result by 0.3

Example: A 2Ah 18650 Li-ion cell has 0.6 grams of lithium content. On a typical 60 Wh laptop battery with 8 cells (4 in series and 2 in parallel), this adds up to 4.8g. To stay under the 8-gram UN limit, the largest battery you can bring on a plane is 96 Wh (and must be in a device).

Tesla's Model S 85 KWH battery is made with thousands of small batteries or cells and would have about 6.8 Kg of lithium or 15 pounds, about $120 worth, based on the above numbers.

Based on some other current EVs that have provided some detail on their batteries, there is about 0.15 Kg lithium per 1KWH so the Model S could have 12.75 Kg or about $230 worth of Lithium, considering a very high price for lithium of $18,000/tonne.

In either case, the amount is significant but the cost of lithium is not a big factor

With both lithium and graphite, there is lots around and it is plentiful.

Most lithium is mined in South America-Argentina, Bolivia, and Chile. Bolivia especially has large reserves in the Salar de Uyuni, a salt flat so huge and blindingly white, that Neil Armstrong and Buzz Aldrin spied it from the moon. (They thought it a glacier.)

The global reserves of lithium carbonate equivalent-which is the amount that can be economically mined right now-is estimated to be about 14 million tons, according to the

United States Geological Survey. (USGS). The actual amount produced each year is very little of this, 32,500 tons - again according to USGS.

With the increase in Lithium prices a lot of money has come into the sector that is bound to bring on new supply

The real issue is ramping up production as demand increases

The market is dominated by a few big producers.

FMC will produce an additional 4,000 tonnes of lithium hydroxide next year, raising the company's total global capacity to 18,000 tonnes. It did not give details of the electric vehicle manufacturer it struck a deal with.

The additional production would be almost enough to supply Tesla's Gigafactory or roughly 500,000 mass-market electric vehicles, according to Aleksey Yefremov, an analyst at Japanese bank Nomura.

However, a point was made that, "The fact that FMC wants to bring incremental capacity on in the near term confirms a tight market for battery grade lithium," Aleksey said.

Australia is the biggest producer, slightly ahead of Chile, and

production is ramping up down under.

There are 16 lithium projects estimated to begin production between 2016 and 2020. The majority of these are hard rock projects, which have the ability to come online relatively quickly (5 years expenditure to production) given their shorter production lead times.

While there could be some timing issues and a bit of a tight market the next year or two. It is already priced in!!!

Graphite

For

Graphite, the USGS lists reserves at 230 million tons and production in 2015 of 1.19 million tons. Although production is about 36 times more than lithium, there is also a lot of synthetic graphite produced. The USGS estimated in 2013, the U.S. consumption of natural and synthetic graphite was 52,200 tons and 159,000 tons respectively.

Simply based on USGS numbers there are 430 years of lithium reserves based on current consumption and 193 years supply of graphite. There appears to be way more lithium available,

but keep in mind that bringing the reserves into production is a whole different matter.

Graphite promoters will claim there is twice as much graphite in a battery than lithium. If you go by weight which is the best measurement, it might be more like 1.6 times

A large EV battery requires about 25kg (55 lb) of graphite for the Li-ion anode, which is around twice the 15 to 28 pounds of lithium I calculated. At 28 pounds lithium, it is close at 1.9 times more graphite.

Benchmark Mineral Intelligence estimates in 2021, based on Tesla manufacturing 150,000 Model 3 units, Benchmark estimates that the company will consume 10,800 tonnes of spherical graphite for its anodes and 7,200 tonnes of lithium hydroxide as a cathode raw material.

That equates to 1.5 times so I would say that 1.5 to 2 times is an accurate number.

So that in itself is more bullish for graphite,

but there are two larger factors at play.

Spherical graphite has to be 99.9% pure carbon and go through a refining process to make and as a result, on average over half the flake graphite mined is lost in the concentration process. So to make ton of spherical graphite you need 2 tons or more of natural graphite produced.

So in essence there is about 3 to 4 times as much graphite required for a battery than lithium.

With lithium, it currently comes out of the mining process at between 90% to 95% pure, so not much waste to get the purity over 99% but it is an energy intensive and expensive process.

There are currently two sources of carbon for the graphite anode. A synthetic process and spherical graphite derived from flake graphite.

Spherical at $3,000 to $4,000 per ton has a cost advantage over synthetic at $10,000 per ton and spherical is far less energy intensify and more environmentally friendly to produce.

The Benchmark article of April 1 also highlights that

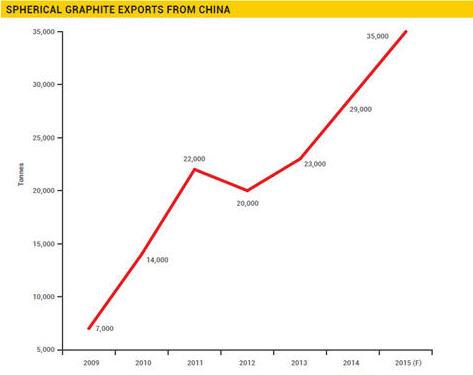

100% of natural spherical graphite is produced in China, and last year alone production expanded by nearly 50%. Increasing demand has seen prices of uncoated spherical graphite increase by 10% in the last two months.

Therefore, on top of battery demand increasing, we are also seeing demand increasing for natural graphite by a further factor because spherical is getting the nod over synthetic and it is believed this is Tesla's preference as well.

Just these two factors means that demand or amount of graphite could outpace lithium demand by a factor of 4 to 6 times as it equates to the battery market.

Most investors fail to understand or to have done the research to uncover these facts.

"

The main determinants on the cost of the cell are the price of the nickel in the form that we need it… and the cost of the synthetic graphite with silicon oxide coating," explained Musk of Tesla.

When you consider that there is more graphite in a lithium ion battery than lithium, the cost of graphite to a battery is more significant than lithium. Currently, the market is just focused on part of the equation and is ignoring graphite - but currently, to our benefit, I might add.

Currently, Tesla sources their cells or batteries from Panasonic that uses synthetic and spherical graphite. However there are two important factors here, the trend towards spherical graphite and the fact that graphite contributes more of the cost of a battery than lithium.

Graphite has not experienced the price spikes that lithium is going through. As a result, graphite's supply situation has fallen under the radar.

There are a couple of other factors that could be very bullish for graphite. Lithium supply is diversified around the world with Australia and Chile as the top producers making up about 10% of supply each. Over 70% of graphite production is from China so any policy change there could dramatically move prices up.

And a 4th and very important factor for investors is that the price of lithium stocks have jumped much higher and graphite stocks have been soft or lackluster.

The old mantra that always proves true is buy low and sell high.

Right now, the majority of investors are doing the opposite, buying the lithium stocks high and not buying the graphite stocks low.

There is nothing wrong with owning lithium stocks and with batteries an important aspect of our future you stand to profit.

However, from what I have uncovered for you here, I believe you should have 4 to 6 times more $$ in graphite stocks over lithium.

(20min delay)

(20min delay)